Why Do You Need a Hydraulic Oil Cooler?

You might think the biggest threat to your hydraulic system is contamination from dirt, water, or air. But you should consider heat as an equally destructive pollutant. Excessive heat degrades your hydraulic oil just as severely, causing just as many component failures. This is precisely why you need a hydraulic oil cooler.

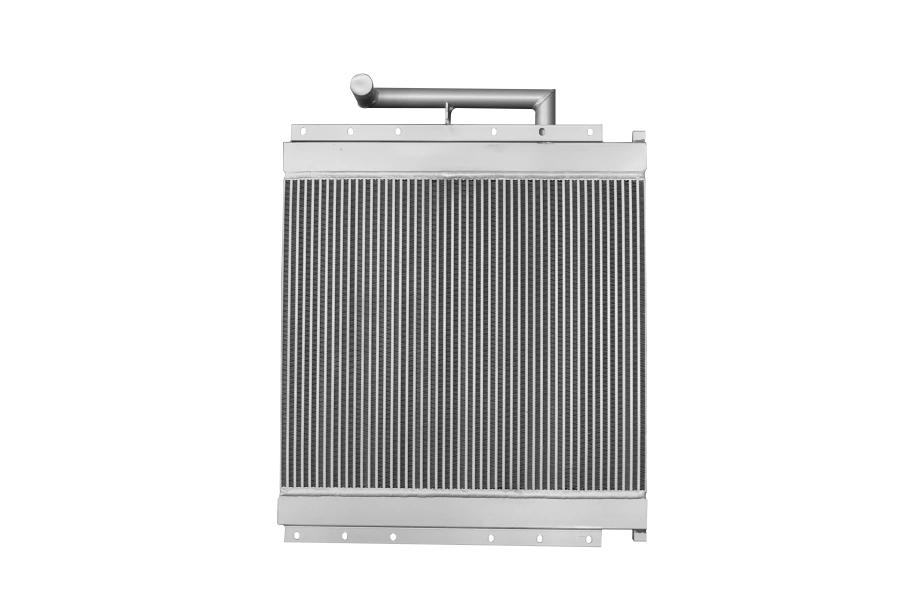

So, what is a hydraulic oil cooler? It is a dedicated heat exchanger for your hydraulic system. Its sole job is to remove the excess heat generated during your operation, transferring it from the hot hydraulic oil to a cooling medium—typically air or water. By installing a hydraulic oil cooler, you actively protect your system from the damaging effects of thermal runaway.

The application of a hydraulic oil cooler is critical in nearly any machine you operate that relies on hydraulic power. From the excavators and presses on your factory floor to the heavy-duty machinery in agriculture and construction, a hydraulic oil cooler works tirelessly in the background. It ensures your oil maintains its correct viscosity and lubricating properties, preventing the oxidation and sludge formation that heat inevitably causes. Simply put, a hydraulic oil cooler is your best insurance for system reliability and longevity.

Why Your Hydraulic System Needs an Oil Cooler – And Likely a LARGE One!

The Problem: Heat as a Primary Contaminant

* Oil Degradation: Heat rapidly oxidizes oil, forming varnish and sludge that clog valves and filters.

* Reduced Viscosity: Thin, hot oil cannot maintain protective lubrication films, leading to accelerated wear of pumps and motors.

* Seal Damage: High temperatures harden and crack seals, causing leaks and allowing external contamination in.

The Consequence: You face frequent breakdowns, high maintenance costs, and shortened component life.

| Why Choosing a LARGER Hydraulic Oil Cooler is the Smart Choice | |

| Key Advantage | Primary Benefit |

| Handles Peak Loads | Effectively manages short-term thermal spikes without being overwhelmed. |

| Provides a Safety Margin | Accommodates future increases in duty cycles, ambient temperatures, or cooler fouling. |

| Operates More Efficiently | Runs at a lower workload, enabling reduced fan speed, lower energy consumption, and quieter operation. |

Investing in adequate cooling capacity from the start saves you money on repairs and downtime in the long run.