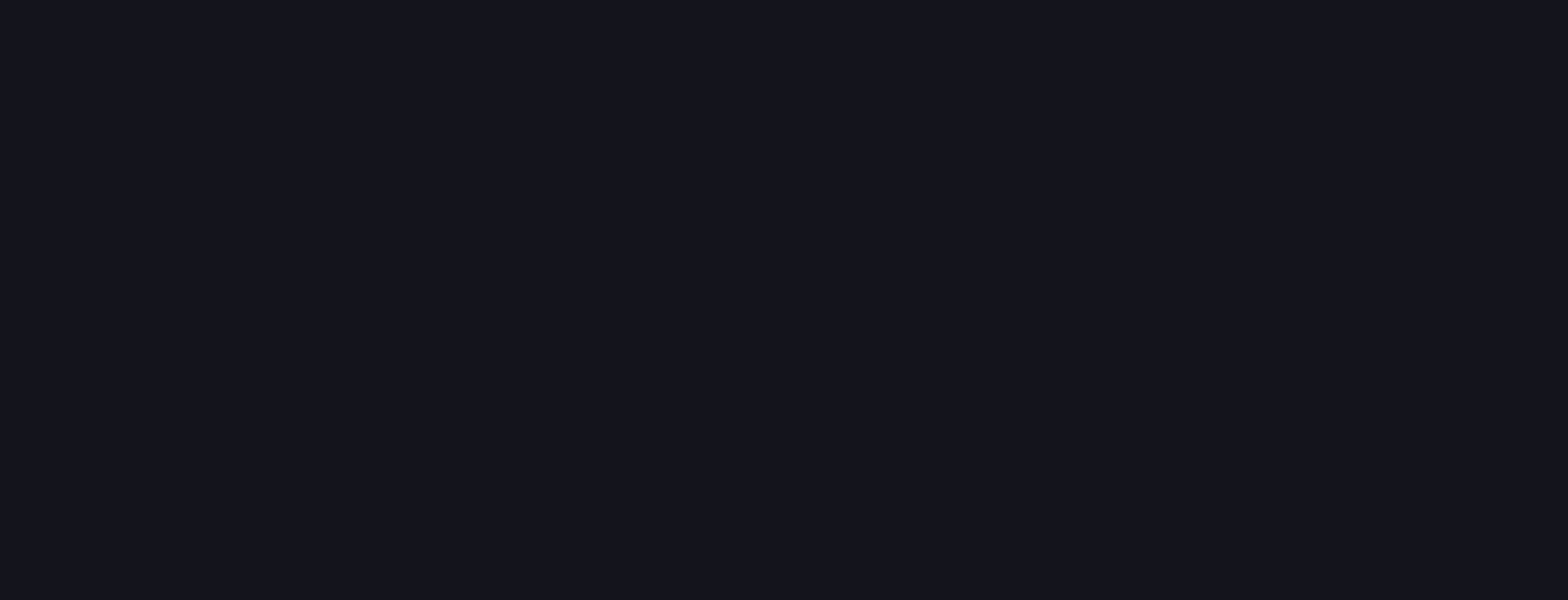

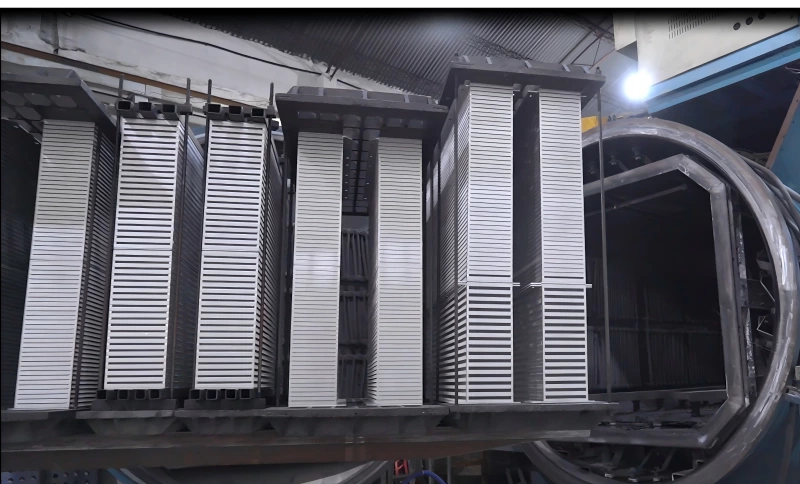

Fin-shaping is the first process in radiator production:

1. Our company operates 12 new-generation fin-shaping machines capable of producing all fin types currently required for radiators;

2. The most commonly used fin types include JC, BY, BW, PZ, and DK;

3. Fin height can be freely adjusted as long as the corresponding sealed bar height is available;

Brand Story: Anti-Leakage Jiushengyuan

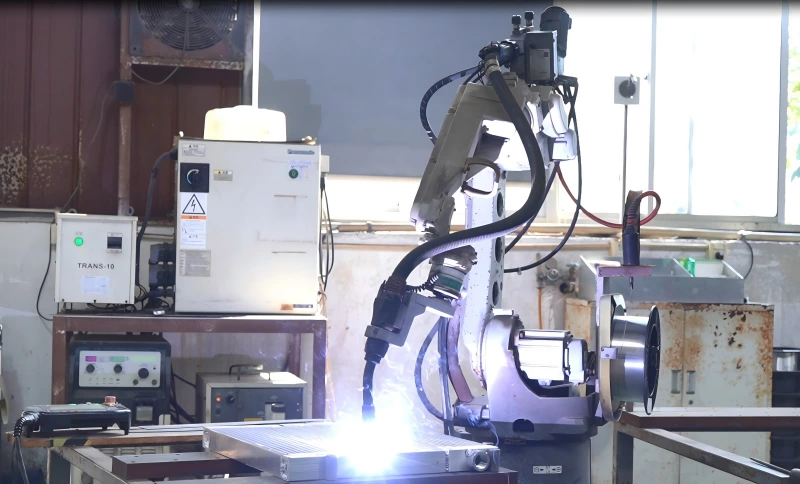

WuXi JiuShengYuan Science & Technology CO.,LTD, established in September 2009 and located within the Mashan Industrial Park in Wuxi, Jiangsu Province, is a leading professional designer and manufacturer of aluminum plate-fin heat exchangers in mainland China. Our company occupies an area of 20,000 square meters and employs nearly 150 staff members, with technical professionals accounting for 20% of the workforce.Our annual heat exchanger production capacity reaches 2,400 tons (approximately 85,000 units/sets).

In January 2011, we successfully obtained ISO 9001 quality management system certification and subsequently earned qualifications and honors including “Jiangsu Provincial Technology-Based SME,” “Wuxi Gazelle Enterprise,” and “Jiangsu Provincial High-Efficiency Energy-Saving Product & Quality Product.” In 2018, we were recognized as a “Jiangsu Provincial High-Tech Enterprise” and have passed annual reviews for multiple consecutive years.

Focusing on leak prevention and energy efficiency, we continuously innovates our products.. So far, we hold 52 authorized utility model patents, 38 invention patents, and 12 design patents.

In May 2010, we officially established our foreign trade department, and by May 2012, we had passed CE certification, marking a new stage of large-scale expansion into international markets. Today, our products are exported to more than 30 countries and regions, including Europe, the United States, Southeast Asia, the Middle East, and India.

Our main products include plate-fin heat exchangers, such as air coolers, water coolers, oil coolers, oil-gas coolers, oil-gas-water combination heat exchangers, automotive intercoolers, and radiators. These products are widely used in air compressors, generators, hydraulic systems, construction machinery, wind power generation, and automotive applications.