Common Cleaning Methods for Screw Air Compressor Radiators

After several years of operation, screw air compressor radiators may develop carbon deposits and coking if unsuitable lubricants are used. At this stage, thorough cleaning of both the external and internal surfaces becomes essential. Below, we outline several commonly employed cleaning methods for screw air compressor radiators, which we hope will prove beneficial for your maintenance tasks.

Online Cleaner Application Conditions:

Light carbon deposits

High-viscosity lubricating oil

High-temperature operation in air compressors

Method:

1. Initiate online operation upon startup, running continuously for 24 hours.

2. Add at a ratio of 1 part cleaner to 18 litres of oil.

3. To prevent resettling of suspended contaminants, drain the oil completely whilst still hot.

Soaking Cleaner Application:

For air compressors seized due to severe carbon deposits and heavy oil contamination.

Usage Method:

Dismantle the main unit and cooler for soaking. Soaking duration depends on carbon thickness and hardness, typically ranging from 20 minutes to 2 hours.

Scale Remover

Application:

Pipework and cooler scale.

Usage Method: 1. Connect the pump, cleaning tank, and equipment to form an independent circulation system. Prepare cleaning solution at 10%-20% concentration for circulation cleaning. (Immersion or scrubbing may be used where circulation is unavailable). Heating accelerates cleaning but liquid temperature must not exceed 60°C. 2. Clean for 1-6 hours depending on scale severity, equipment type, and reaction rate. Flush thoroughly with clean water after draining.

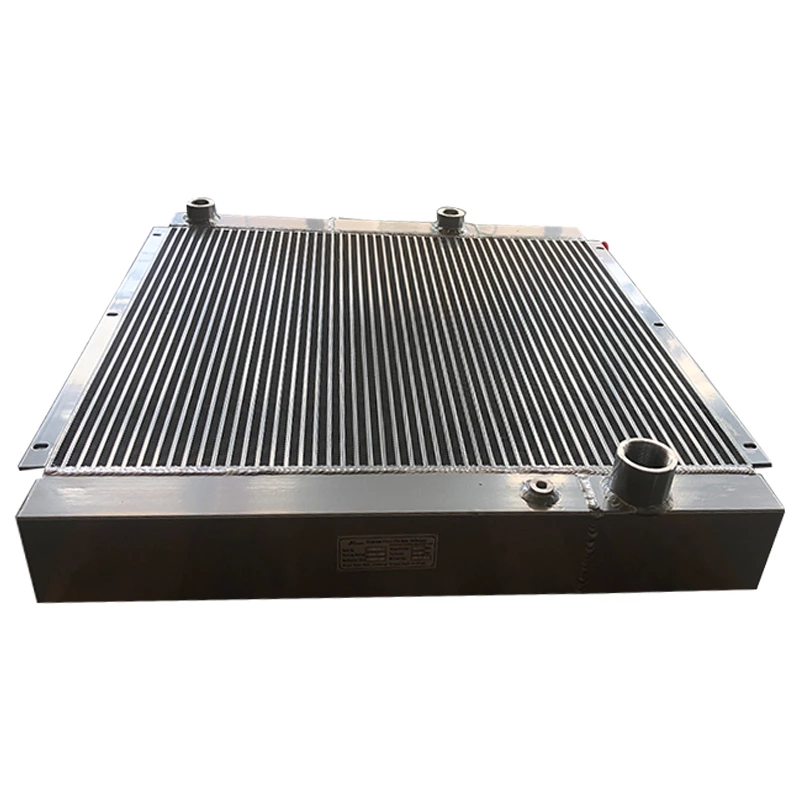

The heat exchanger plays a vital role within the compressor by cooling the machinery, thereby preventing malfunctions caused by excessive temperatures that could disrupt normal operation. Consequently, the solution to heat exchanger blockages lies in thorough cleaning. This prevents clogging of the heat transfer surfaces, which could otherwise lead to high-temperature shutdowns. Such failures would inflict severe operational disruptions upon the equipment user.

Jiushengyuan is a leading professional designer and manufacturer of aluminum plate-fin heat exchangers in mainland China.Focusing on leak prevention and energy efficiency, we continuously innovates our products.

Our main products include plate-fin heat exchangers, such as air coolers, water coolers, oil coolers, oil-gas coolers, oil-gas-water combination heat exchangers, automotive intercoolers, and radiators. These products are widely used in air compressors, generators, hydraulic systems, construction machinery, wind power generation, and automotive applications.

If you are looking for a air compressor coolers for your screw air compressor,welcome to contact us.

E-mail:amanda@china-heatexchanger.com