| Brand Name |

JSY |

| Product Name |

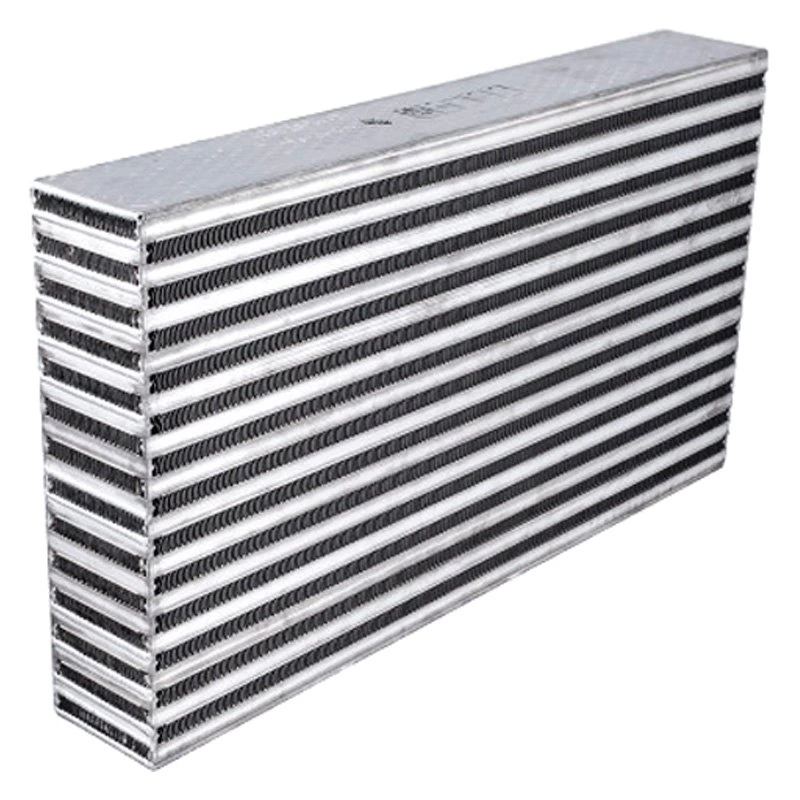

Water-Cooled Core JSY2576 |

| Model Number |

JSY2576 |

| Material |

aluminum alloy |

| Weight(kg) |

8kg |

| Core size(mm) |

635*320*55 |

| Structure |

Plate-Fin |

| Color |

Silver/ Black |

| Intercooler capacity |

for retrofit/upgrade |

| Purpose |

OEM/ODM |

| Application |

Auto Cooling System |

Features of the Custom Air to Water Intercooler Core JSY

1. Highly flexible design, customizable to meet customer requirements;

2. A variety of fin specifications to meet resistance requirements;

3. Utilizes a world-leading vacuum brazing furnace, achieving a first-pass yield of 98%;

4. Withstands pressure exceeding 4.0 MPa.

Application Scenarios for Custom Air to Water Intercooler Core JSY

It can be applied to various plate-fin heat exchangers and is particularly suitable for applications with high pressure and vibration requirements, such as construction machinery and heavy trucks.

Frequently Asked Questions (FAQ)

1. What types of fins do you offer?

We offer flat fins, perforated fins, louvered fins, serrated fins, and corrugated fins.

2. Can your heat exchangers be customized?

Yes, we offer multiple specifications and customization services. You can specify requirements based on your equipment's operating environment, installation dimensions, pressure, and heat dissipation needs. Our engineering team will design a tailored solution for you.

3. How do I select the right heat exchanger for my equipment?

Provide us with your equipment's basic parameters (e.g., power rating, working medium, inlet/outlet temperatures, installation space). We will recommend the most suitable radiator model or custom solution based on actual operating conditions.

4. What product specifications do you offer?

We provide standard models including automotive intercoolers, air compressor radiators, and industrial machinery radiators. We also support custom specifications and high-power equipment. Refer to our product catalog or contact our sales team for detailed specifications.

5. What is your delivery time?

For in-stock products, our delivery time is generally 7-10 business days. For custom products, our delivery time is 20-30 business days after receiving your deposit. Custom products depend on the complexity of the design and the factory's production schedule; we will provide an accurate delivery schedule after order confirmation.

6. How do you ensure product quality?

Our factory is equipped with advanced vacuum brazing furnaces, fourth-generation cleaning equipment, and a comprehensive inspection and performance testing system. Each unit undergoes rigorous airtightness, pressure, and performance testing to guarantee high efficiency, reliability, and durability.

7. Which industries are your heat exchangers suitable for?

Our products are widely used across multiple sectors including automotive, air compressors, construction machinery, metallurgy, hydraulic equipment, and mining machinery.

8. Can you provide samples?

We can supply samples based on your requirements. Please contact our sales representative for specific details and confirmation.