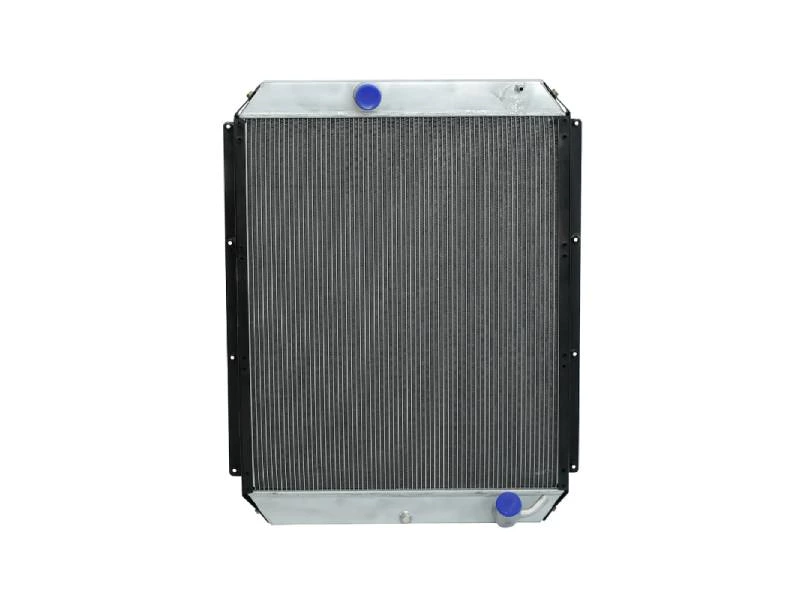

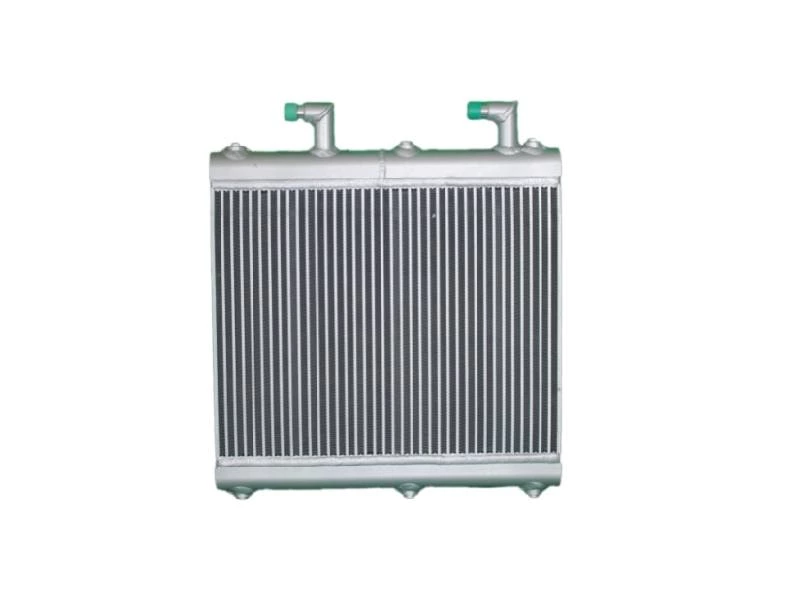

The Radiator Assembly/Cooler meets Volvo's stringent equipment standards, featuring aluminum plate-fin technology for enhanced cooling precision. Its vibration-damping frame and multi-layer cooling channel design ensure low-energy consumption and quiet operation, meeting environmental and high-performance requirements.

| Product Name |

VOLVO Excavator Radiator Assembly/Cooler |

| Materials |

Aluminum Alloy |

| Operating Temperature |

-40℃-60 ℃ |

| Tonnage |

1.7 t - 100 t |

Key Features of VOLVO Excavator Radiator Assembly/Cooler

1. High-Efficiency Heat Transfer Performance

Manufactured with high thermal conductivity aluminum alloy, this radiator ensures excellent heat dissipation efficiency. It rapidly reduces intake air and hydraulic oil temperatures, helping maintain stable engine performance even under heavy-duty operating conditions.

2. Excellent Strength and Pressure Resistance

Designed to withstand pressure fluctuations commonly found in excavator cooling and compressed air systems, the radiator offers outstanding structural strength, high reliability, and extended service life.

3. Superior Atmospheric Corrosion Resistance

The aluminum construction provides strong resistance to atmospheric corrosion, ensuring long-term durability in outdoor, high-humidity, and dusty working environments.

4. Cost-Effective Cooling Solution

With optimized material selection and manufacturing processes, this radiator delivers excellent performance at a highly competitive price, offering exceptional value for Komatsu excavator replacement and OEM applications.

5. Advanced Anti-Vibration Structure for Harsh Conditions

Equipped with a newly designed vibration-damping frame, the radiator effectively absorbs mechanical vibrations. It performs reliably in harsh environments such as construction sites and mining operations, making it an ideal cooling solution for heavy-duty machinery.

| water |

325*720*80 |

EC80 |

oil |

480*555*40 |

EC55B/C |

| 730*980 |

EC130 |

615*620*75 |

EC140B |

| 368*800 |

EC140B EC135B |

800*600*65 |

EC210B(Old Version) |

| 895*900*72 |

EC210B |

760*330*145 |

EC210B( New Version) Electronic Fuel Injection |

| 720*345*145 |

E210B |

750*370*113 |

EC2109(New Version) |

| 290*875*145 |

EC210D |

990*555*80 |

EC240B(Old Version) EC290B(Old Version) |

| 310*870*145 |

EC220D |

710*450*115 |

EC240B(New Version) EC290B(New Version) |

| 791*598*146 |

EC240B EC240C

EC290C EC290B |

980*480*113 |

EC250D |

| |

EC240B |

750*540*160 |

EC360B |

| 638*1000*146 |

EC360B EC330B EC330C

EC460B EC480D EC360C

EC460C EC380D |

750*770*140 |

EC460B EC460C |

| 505*1375*146 |

EC480 |

820*820*140 |

EC480 EC480D EC480DHR |

| 714*1120*146 |

EC480 |

|

|

|

| 715*1200*146 |

EC700B |

|

|

|

| 715*1120*146 |

EC700C |

|

|

|

| |

EC750

EC950 |

|

|

|

| 560*550*55 |

EC55C |

|

|

|

| |

EC55D |

|

|

|

| 688*1120*146 |

L180E L150E L150F

L220E L180F L220F |

|

|

|